Energy & Waste to Energy

Filtration steps on the gaseous effluents are essential to ensure the neutralization of pollutants

In plants for the production of electrical energy by combustion, filtration steps on the gaseous effluents are essential to ensure the neutralization of pollutants and the dedusting of fumes.

The variability of the operating conditions and the type of fuels, as in the case of biomass plants, requires a targeted and effective choice of the filter medium to ensure total compliance with the emission limits against high levels of efficiency and durability.

In some plants, further solid-liquid separation processes are also required for the dehydration and recovery of the gypsum produced by the desulphurization of gases.

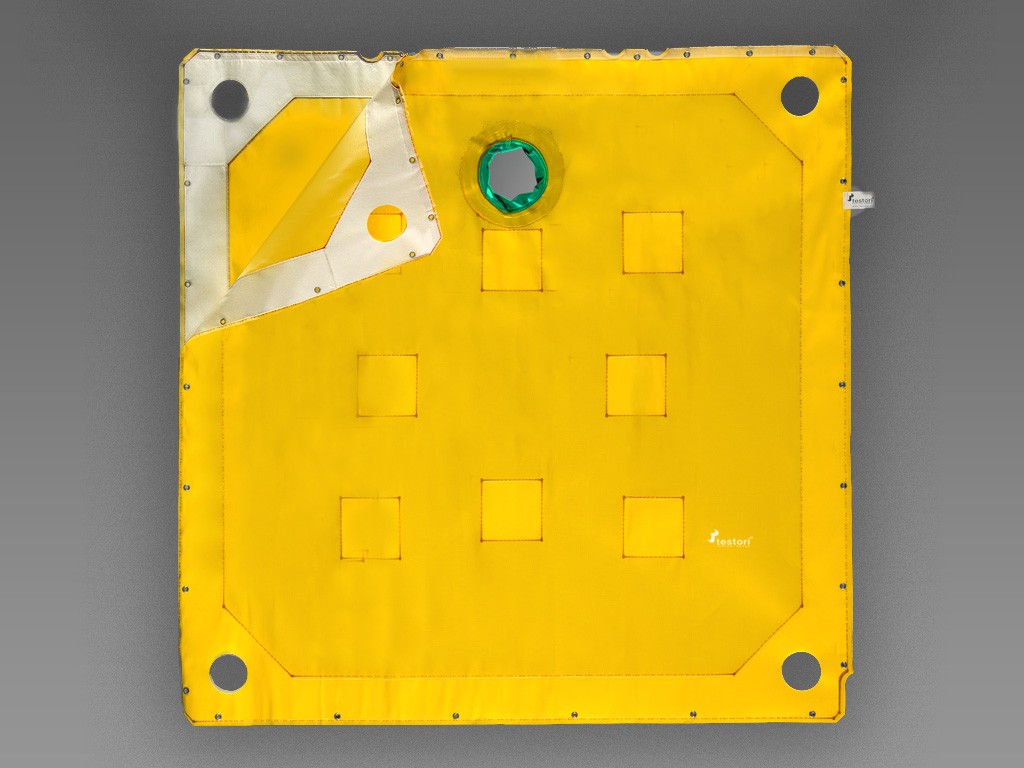

Thanks to its vertically integrated production cycle and its extensive experience, Testori is able to offer a wide range of products specifically developed to meet all customer needs for each configuration of its plant: dry / wet / semi-dry desulfurization.

Filter media based on special fibers such as PTFE, PPS, P84®, mixed PTFE / P84®, acrylic and glass fiber, also available with special treatments and in multilayer configurations, are able to guarantee high levels of filtration efficiency to manage distribution of particularly fine powders.

Testori supports all types of customers along the specific supply chain: manufacturers, machinery builders (OEMs) and end users.

Products

Concept, Design, Customization

Testori, the solution for every application

#test-us