Aluminum & Alumina

The aluminum and alumina industry includes different process stages in which filtration plays an essential role.

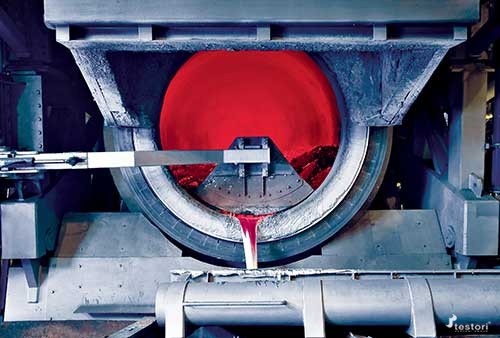

From solid gas separation such as GTC (Gas Treatment Center) on electrolytic cells, FTC (Fumes Treatment Center) on anode firing ovens and combined layouts (F & GTC), to the separation of mother liquor and FDL, continuing in the different washing phases of the precipitate up to the dehydration of the red sludge.

Thanks to its consolidated experience in the field, Testori offers specific products for all filtration needs through the different stages of alumina production, in the process of making primary aluminum and in foundries for the refining of secondary aluminum. Special treatments and microfibers are the main solutions to the problems of abrasion and formation of hard gray scaling generated in the “potlines”, while our acrylic felts perfectly meet the need for reducing carbon residue packing in FTCs. Our range of filter media, bags and multi-channel bags allows us to satisfy every request, to reach the highest standards of efficiency in the main solid gas separation processes.

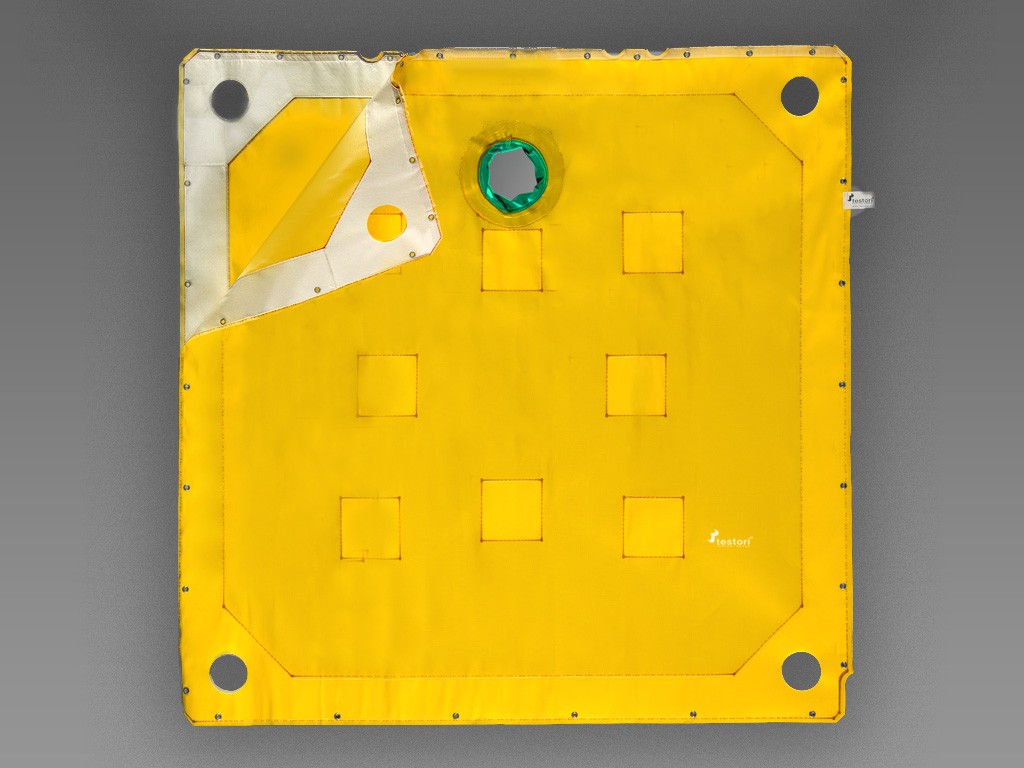

Likewise, all of our specific products such as multi-channel bags for Kelly and Diastar filters, cloths for filter presses and drum filters, sectors for pan and vacuum filters, guarantee the best performance in liquid filtration.

The aggressive chemical conditions, abrasion and scaling typical of Kelly and Diastar filters are counteracted by the use of high strength fibres (special polyamides and fluorinated polymers) and special tailoring accessories (top cuff). The use of very resistant and high-weight fabrics guarantees high drainability and excellent retention of particles in the filter presses, which, with the addition of special treatments and unique tailoring details nearby the holes (distribution ring or collar), ensure high abrasion resistance. Special elastic fabrics have also been designed to adhere perfectly to the drum filters and favor a better detachment of the cake, thus reducing the clogging of the filter medium and supporting a high productivity of the system.

Our fluidization fabrics also provide targeted solutions for the handling and storage of powders.

Testori supports all types of customers along the specific supply chain: manufacturers, machinery builders (OEMs) and end users.

Products

Concept, Design, Customization

Testori, the solution for every application

#test-us